-

Carbide Milling Inserts

-

Tungsten Carbide Inserts

-

Milling Cutter Carbide Inserts

-

Indexable Milling Inserts

-

Cemented Carbide Inserts

-

Indexable Carbide Inserts

-

High Feed Milling Inserts

-

Chip Breaker Inserts

-

Carbide Inserts For Aluminum

-

Carbide Turning Inserts

-

CNC Carbide Inserts

-

Woodworking Carbide Inserts

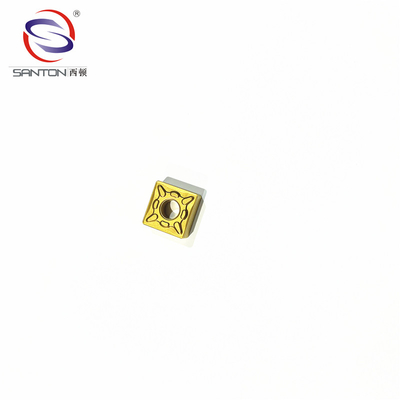

YG8 Milling Cutter Carbide Inserts High Precision C1 ANSI CNC

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Grade | K30 | Color | Golden Or Black |

|---|---|---|---|

| Machinery Test Report | Provided | Material | Tungsten Carbide |

| Alias | Cutting Tool | Marketing Type | Ordinary Product |

| Local Service Location | None | Product Name | Good Durability CNC Carbide Inserts |

| High Light | YG8 Milling Cutter Carbide Inserts,CNC Milling Cutter Carbide Inserts,C1 ANSI CNC Milling Inserts |

||

Good Rigidity High Precision Good Durability CNC Carbide Inserts

Product Information:

In order to achieve efficient, multi-energy, fast change, economic purposes, CNC machining tools and ordinary

Metal cutting tools should have the following characteristics:

The tool should have high precision, including the shape precision of the tool blade and the relative position precision of the tool handle to the spindle of the machine tool

Repeat accuracy of transposition and disassembly of blade and handle.

The shank should have high strength, rigidity and wear resistance.

There is a limit to the weight of the handle or tool system.

The position and direction of cutting blade and handle are required.

The positioning datum and automatic tool changing system of blade and handle should be optimized. The cutting tools used on CNC machine tools should meet the requirements of installation and adjustment convenient, good rigidity, high precision, good durability and other requirements.

Grade & Application:

| Santon Grade | ISO Grade | ANSI Grade | Physical and Chemical Property | Performance & Applications | ||

| Density | TRS | Hardness | ||||

| g/cm3 | n/mm2 | HRA | ||||

| YG8 | K30 | C1 | 14.7 | 2520 | 90 | High strength, better impact and shock resistance, but lower wear resistance and cutting speed. Suitable for roughing of cast irons, non-ferrous metal, alloys, and non-metallic materials at low speed. |

![]()

Certifications:

![]()

Company information:

Cutting tool downstream application is very wide, at present, the domestic cutting tool products have a greater demand for key industries are: automotive industry enterprises; Top ten industrial groups in aviation, aerospace, weapons, shipbuilding and nuclear industry; Machinery, railway locomotive, mold, textile, energy equipment, agricultural machinery, major complete sets of equipment manufacturing enterprises.

Welcome to contact us.

![]()

![]()

![]()

FAQ

Q. Are you a manufacturer or a trading company?

A. We are a professional manufacturer with 10 years of experience of producing and selling carbiede inserts.

Q. What is your main products?

A. Our main products includes cemented carbide plates, strips, blanks, saw tips, geological and mining bits, brazed tips, indexable carbide inserts, wear parts,snow plow inserts, tungsten carbide pins, etc.

Q. what's the payment term?

A. We accept Western union, Onetouch, T/T, and L/C. 30% T/T deposit and 70% balance before shipment, or against copy of BL, or L/C at sight.

Q. What about your delivery time?

A. Usually it will take about 25 - 30 days for production.But for new molds, the lead time may need 10days more to open molds. If you need the goods urgently, we could try to push for and shorten the delivery time.

Q. What is your minimum order quantity(MOQ)?

A. No limit for MOQ. For non-standard products, mold fee need to be paid, but can be refunded later.

Q. What is your warranty?

A. We extend a 100% satisfaction guarantee on all items. if you’re not completely satisfied with our products ,we’ll replace them or refund the fee

Q. Where is your market?

A. Our products are popular in Germany, America, Mexico, India, Russia, Indonesia, Malaysia, Bangladesh, South Africa,etc.