-

Carbide Milling Inserts

-

Tungsten Carbide Inserts

-

Milling Cutter Carbide Inserts

-

Indexable Milling Inserts

-

Cemented Carbide Inserts

-

Indexable Carbide Inserts

-

High Feed Milling Inserts

-

Chip Breaker Inserts

-

Carbide Inserts For Aluminum

-

Carbide Turning Inserts

-

CNC Carbide Inserts

-

Woodworking Carbide Inserts

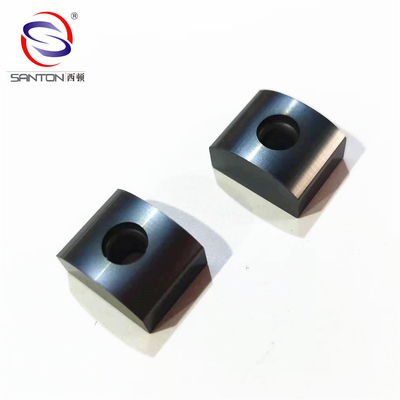

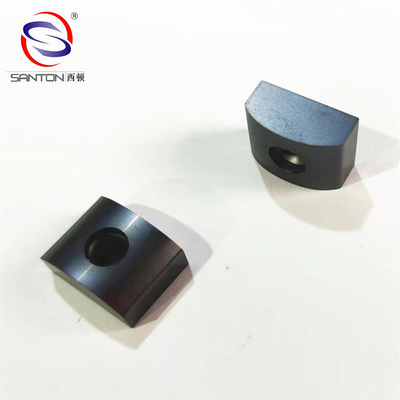

Heavy Milling Carbide Milling Inserts Finishing ANSI C6 Custom Carbide Inserts

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Grade | P25~P45 | Port | Shanghai,Shenzhen |

|---|---|---|---|

| Size | ISO Standard, Also Can Be Customized | Usage | External Turning Insert |

| Hardness | 90.4-91.5HRA | Product Name | Heavy Milling Carbide Milling Inserts |

| Model Number | Custom | Surface Treatment | Coated |

| High Light | Heavy Milling Carbide Milling Inserts,Carbide Milling Inserts ANSI C6,ANSI C6 Custom Carbide Inserts |

||

Suitable For Finishing And Heavy Milling Carbide Milling Inserts

Product Description:

Advantages

Stable and best production ability.

Made from 100% virgin raw material.

All products go through in-process and final inspection, must be inspected strictly and only those with out any harm can be shipped out.

produced with advanced equipments and perfect workmanship.

Grade Information:

| Santon Grade | ISO Grade | ANSI Grade | Performance & Applications |

| ST2135 | P25~P45 | C6~C5 | CVD coating, golden. Very high strength and toughness edge matrix, in optimal combination with TiC, AI2O3, TiN coating. A versatile grade for roughing of steel, especially for heavy-duty roughing of cast steel and forged steel. |

Certifications:

![]()

Company Information:

Since 2007, Sonton is dedicated to supplying customers with premium quality carbide products. with 112 employees, advanced own manufacturing facility and carbide binding technology--Paraffin binder. Focus on general ISO inserts, woodworking insert,heavy-duty machining inserts for special applications like railways track/wheel machining inserts, gear machining inserts, crankshaft machining inserts etc.

The company has stronger capabilities of independent R&D, design and production, became quality management system ISO9001:2015, environmental management ISO14001:2015, and occupational health and safety management system OHSAS18001:2007 certified, able to provide users with pre-sales, in-sales and after-sales services in technology and application.

Welcome to use 'Santon' brand products

![]()

![]()

![]()

FAQ:

Q. Are you a manufacturer or a trading company?

A. We are a professional manufacturer with 10 years of experience of producing and selling carbiede inserts.

Q. What is your main products?

A. Our main products includes cemented carbide plates, strips, blanks, saw tips, geological and mining bits, brazed tips, indexable carbide inserts, wear parts,snow plow inserts, tungsten carbide pins, etc.

Q. what's the payment term?

A. We accept Western union, Onetouch, T/T, and L/C. 30% T/T deposit and 70% balance before shipment, or against copy of BL, or L/C at sight.

Q. What about your delivery time?

A. Usually it will take about 25 - 30 days for production.But for new molds, the lead time may need 10days more to open molds. If you need the goods urgently, we could try to push for and shorten the delivery time.

Q. What is your minimum order quantity(MOQ)?

A. No limit for MOQ. For non-standard products, mold fee need to be paid, but can be refunded later.

Q. What is your warranty?

A. We extend a 100% satisfaction guarantee on all items. if you’re not completely satisfied with our products ,we’ll replace them or refund the fee